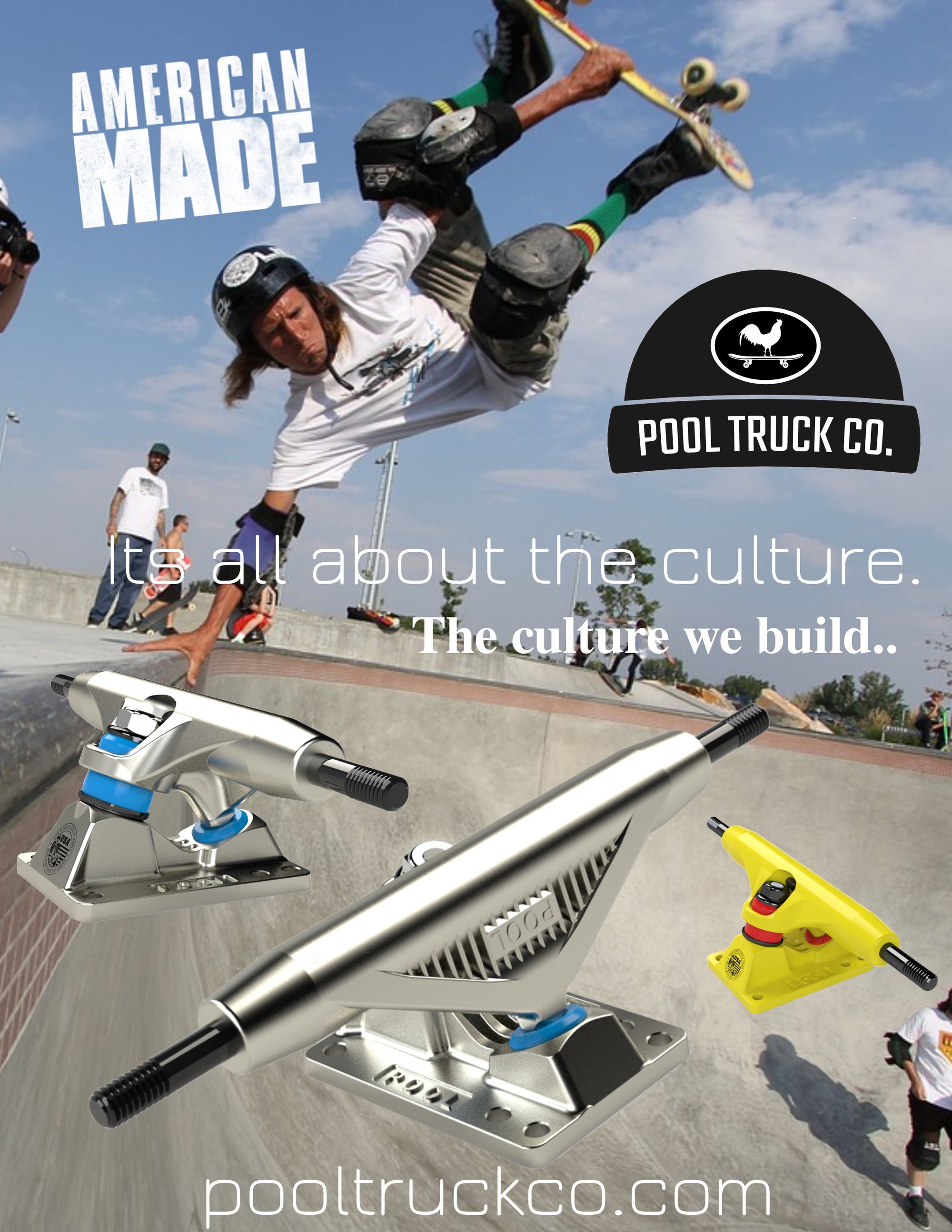

The Pool Truck Project

POOL TRUCK CO is completely made up, but this would kick ass and you may be able to help make it happen

If you can help get the letter below to Tim Pool or his crew, I will do what I can to make it happen from there. Typical means of contact seem to be disabled.

My name is Darrick Medina and I build things.

The Purpose of this Project is to set-up production of the trucks and decentralize the process to independent operators. It would make for a great example of a decentralized process and inspire at-home manufacturing and automation.

A Letter To Tim Pool

Hi Tim, I hope this message finds you well.

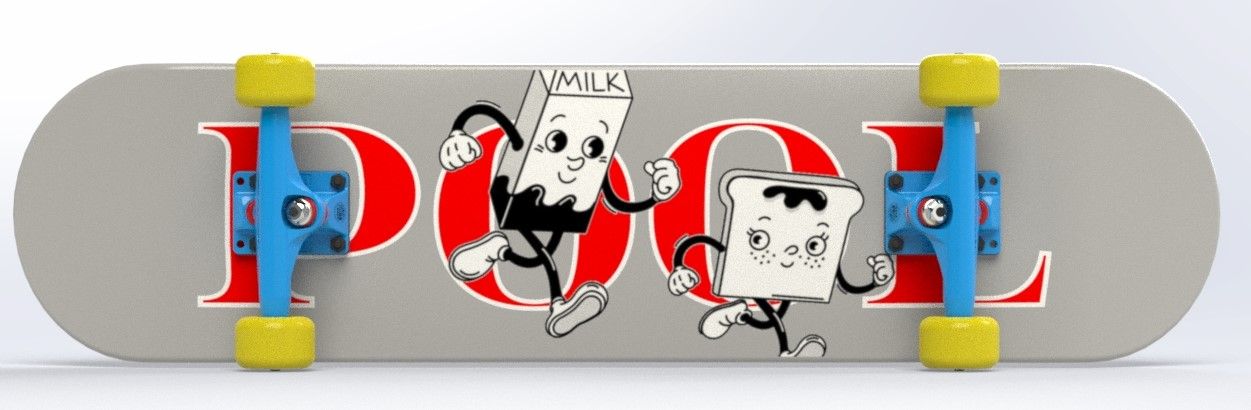

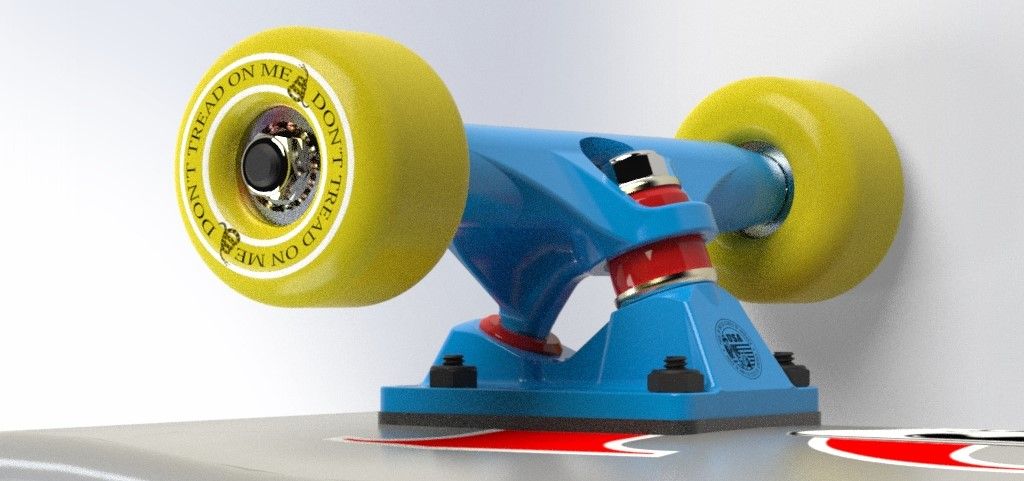

My name is Darrick Medina "The Machinist", and I created these trucks and the company concept. I created it as the first stage of a project to show people how to manufacture products in small home based shops and live an independent, family based life. Truth is, these trucks can be produced on equipment that costs less than half the average price of a used car. The equipment would fit comfortably in a small shop or garage. The Trucks would be a nice product addition to your skate shop. I don't sell anything Tim. I have solutions and I want to bring them forward.

I would like to set up shop for you and decentralize the process.

The design rights, CAD files, and my manufacturing process recommendations are yours Tim, as a gift from me to you if you would like to pursue manufacturing of the trucks. I even grabbed the domain just in case. I would love to make this happen for you Tim. Please take a moment to look over my background. I can build anything.

What I would get out of this endeavor

I don't want to take your time Tim, what you are doing is very important. I would like to set the process up for you and share the process of creating a real product with your viewers. As you are well aware, many people hold back on speaking up about important issues due to fear of losing hard earned positions in companies that employ them. I want to reach as many people as possible and give them a path to making a living outside of the machine. Where independent manufacturing can bring all of the profit to the owner of the skill and the time at home will allow you the time to maintain a healthy family lifestyle.

Your viewers trust you Tim. Give me a shot at contributing to this culture war on a new front with a much bigger impact. Your viewers will trust you to call me out if I fall short on providing everything I claim. I wont be charging for anything that promotes manufacturing independence. Once I have successfully set up shop and trained someone to run the process, I will continue the cycle with individuals such as your viewers, continuing to promote the culture and creating content through example and collaboration.

I would love the opportunity to discuss the solutions decentralized manufacturing will contribute to. Solution contributions to issues like bringing manufacturing back, product shortages, the manufacturing skills gap, and building a solid family foundation.

Thanks for your time Tim/Crew, I hope to hear from you.

Darrick Medina "The Machinist" dmedina@decentralizedmfg.com

I see the writing on the wall. In-home manufacturing utilizing CAD and small-scale manufacturing techniques will become common place with the ease of use of engineering software and AI. The available small-scale equipment for in-home manufacturing is affordable and much of the equipment can be made through designs published online. I have the knowledge and familiarity with the manufacturing processes to bring them forward and explain the possibilities of a future in in-home manufacturing. We are proposing a Decentralized Manufacturing industry. An industry comprised of Independent Operators (IO’s) manufacturing quality products on a small scale from home.

The capabilities of mechanical engineering software have reached a point where average people can get free training and run complicated analysis of products on an engineering level. Most of the complicated analysis like stress, thermal, particle/fluid flow, and complex assembly is done by the software. Engineering is ready for the masses, and we will be showing countless examples of as many of these abundant opportunities as possible, both personally and through social media videos by content creator's review.

The system put in place will be a parallel manufacturing industry of in-home manufacturers and in-home product designs. A network will be created to connect these manufacturers. This network will enable them to work together to create quality products with low overhead costs with the ability to sell directly to the masses as well as meeting local community needs with goods. This decreases the hold that the Tech Oligopoly has on the manufacturing industry and puts the power of manufacturing back into the hands of the individual people creating the products. As a prominent member of this current Manufacturing industry, I can tell you with certainty, the current manufacturing industry and tech will not be able to keep up with the in-home manufacturing industries development speed.

I will take the chance of sounding overconfident by saying the chances of success are very high. With my love for creating and building, it comes natural for me to share inspiration to create great things. I have never failed to create what I said I could, and I have created many things that have never been created.

More to come!

The Machinist