Darrick Medina

Manufacturing Superfreak

I have had an extensive career as a Journeyman Machinist moving up to Engineering Manager. Fortunately for me, I was able to climb the ladder through every position along the way. I have learned every machine and process I could get in front of. I have worked for Fortune 500 companies and have designed or produced products used in almost every industry. As a Manufacturing Engineer/Consultant, I have developed some of the most efficient processes and systems in the manufacturing industry.

Below are some examples of my work as well as a list of career experience.

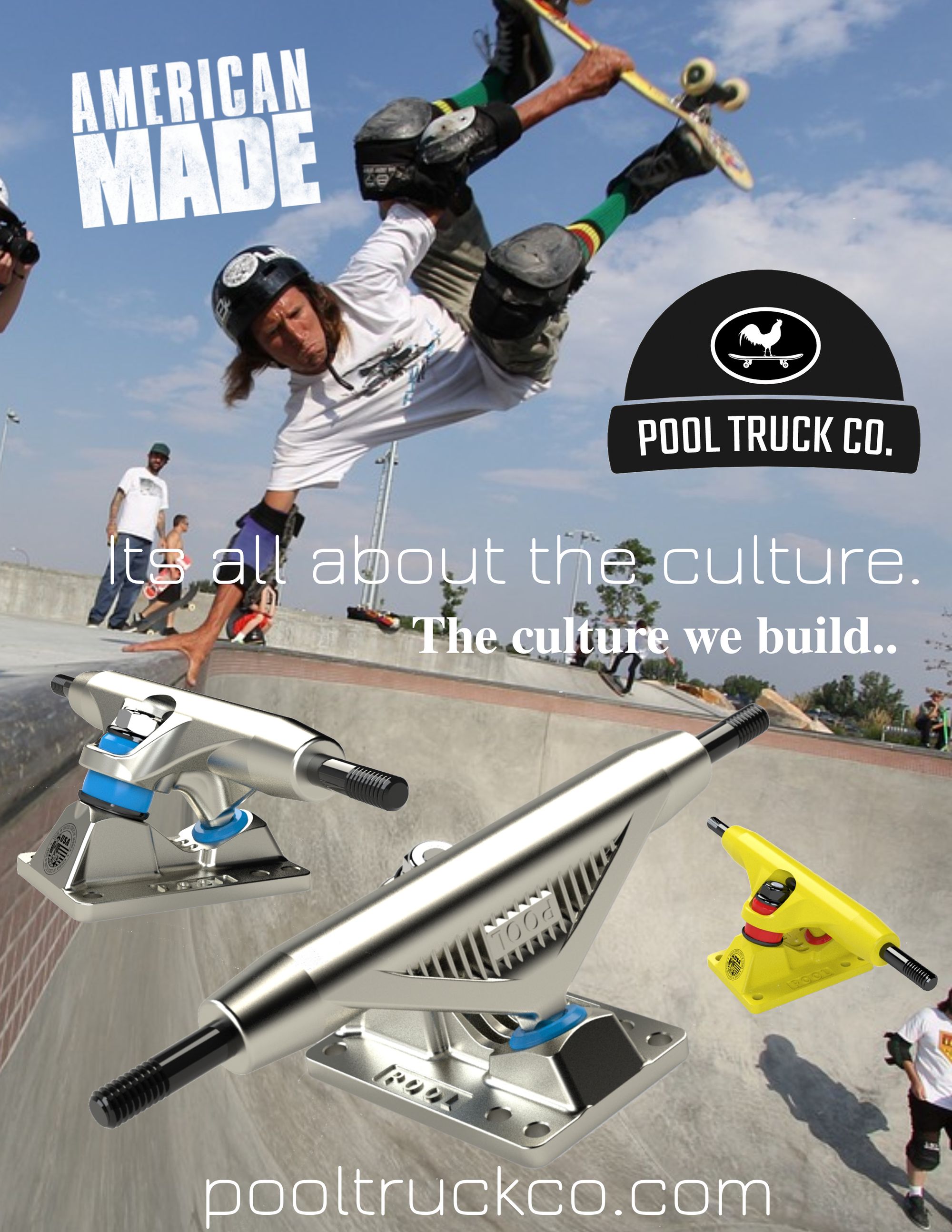

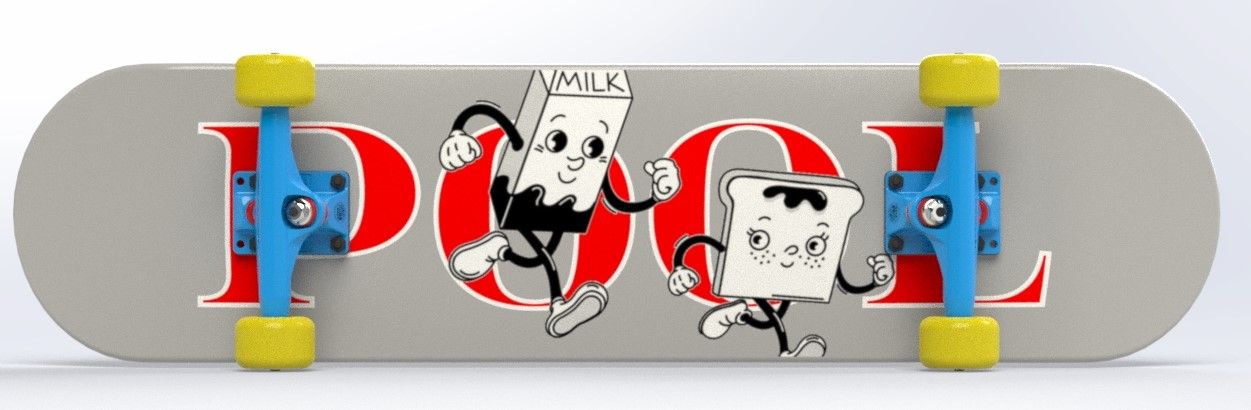

POOL TRUCK CO Advertisement

This is a fictional company used for examples of my skillset. All images, videos, and virtual models for POOL TRUCK CO were created by Darrick Medina.

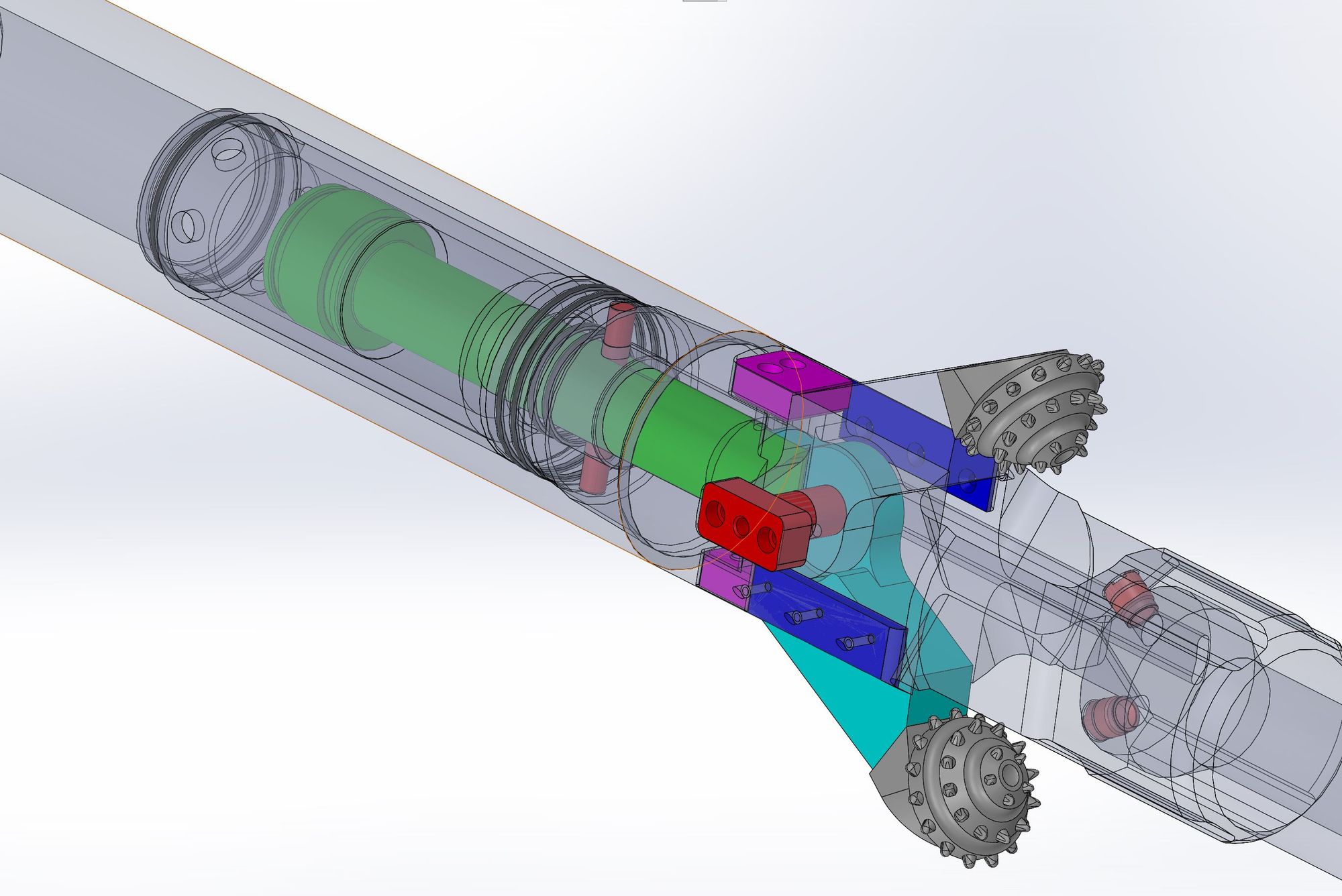

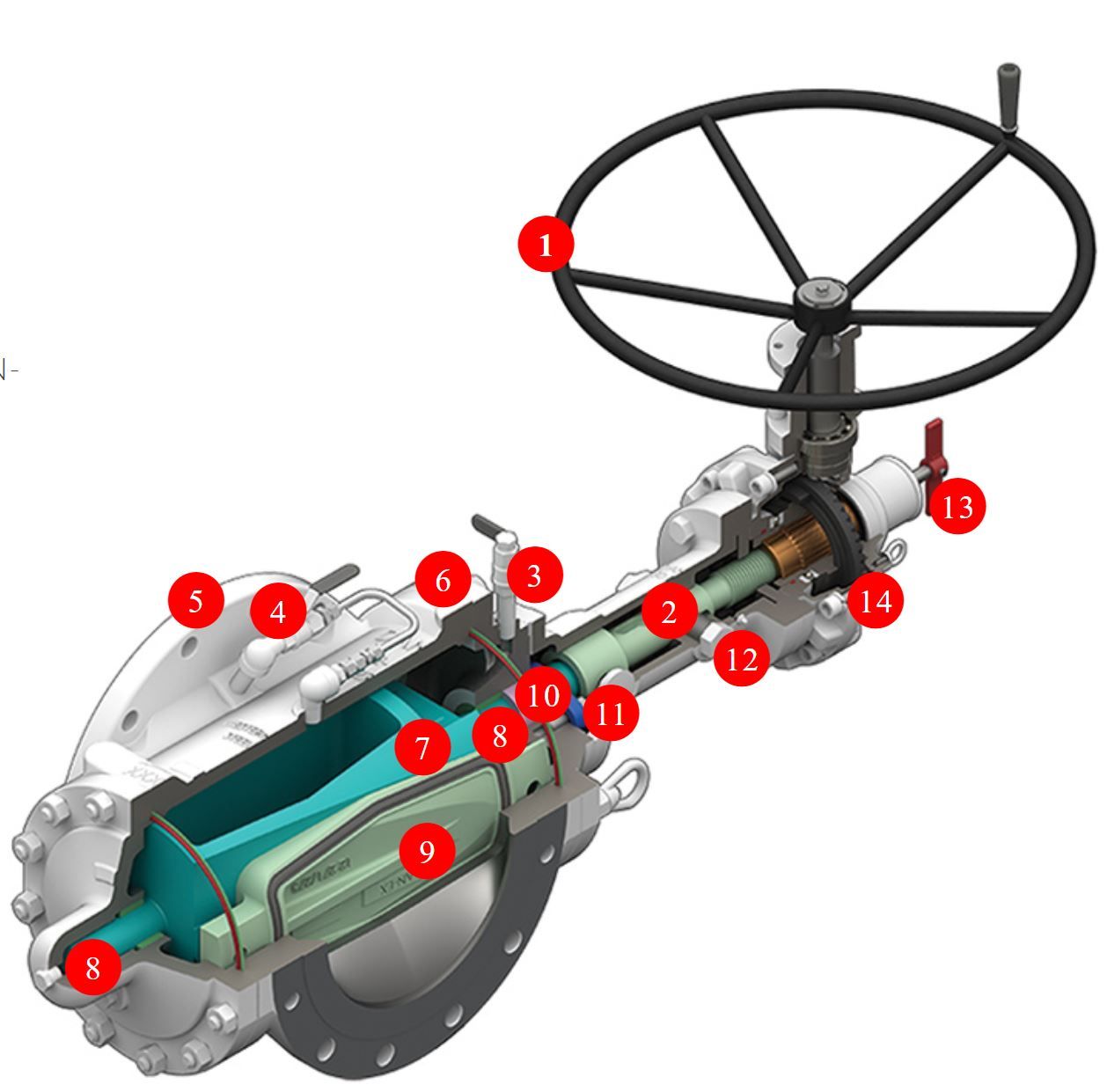

Mechanical design:

- Solidworks Certified Professional

- Sheet metal design

- Advanced surfacing

- Assemblies and mechanical verification

- Forging and casting design

- Stress, flow, and mechanical analysis

- Design for manufacturing (minimize operations/tool design)

- Design for sustainability (fasteners/materials)

Prototyping:

- CAD/Drafting

- Product Assessment

- ROI analysis

- Virtual Product Images/Video

- Promotional Image/Video Ads

- Journeyman Machinist

- 3D printing

- CNC programming

- CNC set up and operations

- Welding (stick/mig)

- Plasma / water jet and press brake operations

Production:

- Team building and training

- Procurement

- Complete and detailed blueprints

- Shop layout

- Process control / Time management

- Fixturing

- CNC programming with Mastercam (G-code/Vector code)

- Ability to edit code to suit a CNC machine without the proper machine post

- Machine set up documents and job travelers

- Data management

- Tooling / fixture organization

- Quality control process and documentation

Positions held by employers:

- Manual Machinist

- Tool and die machinist

- Machinist

- CNC operator

- CNC Programmer

- Production lead

- Machine Shop Supervisor

- Production planner

- Metals fabrication supervisor

- Mechanical designer

- Mechanical engineer

- Engineering Manager

- Manufacturing manager

- Manufacturing engineer

Notable Career Highlights:

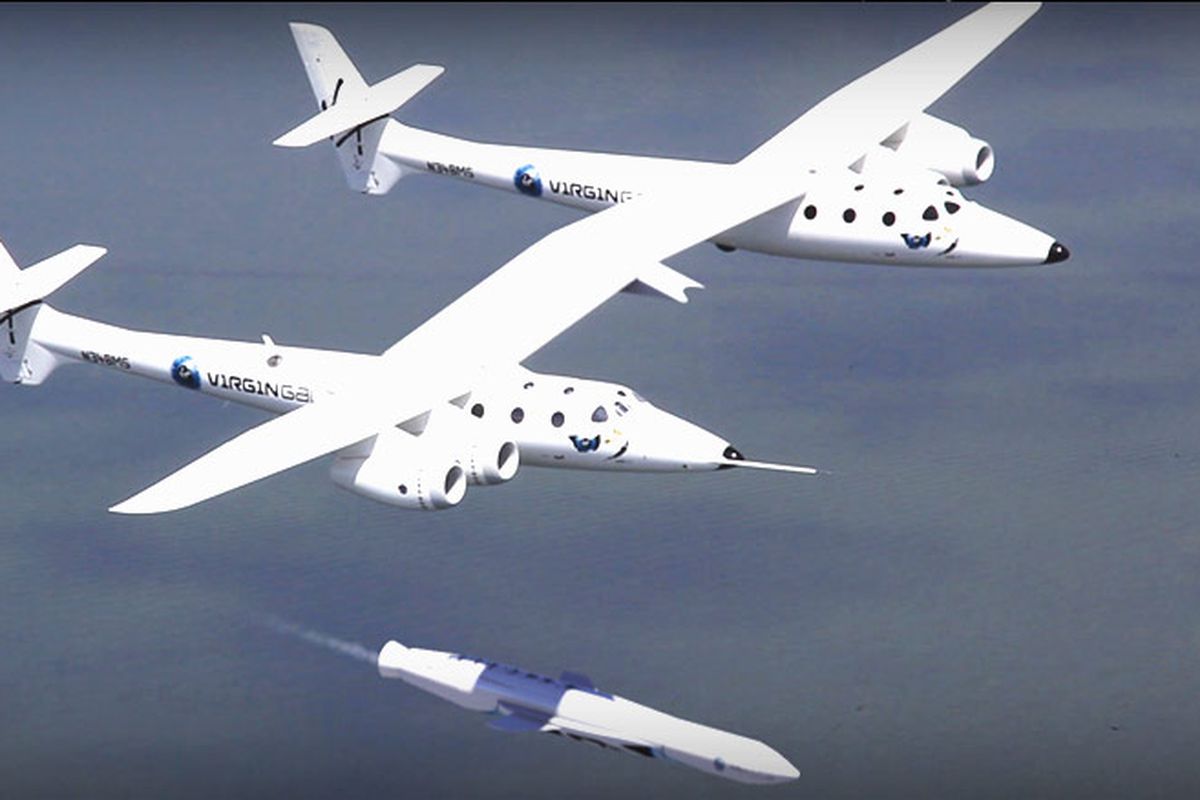

- Metals manufacturing oversight of Virgin Galactic's prototype rocket for the Launcher One program

- Oversight and team member build of Unity 21 spacecraft for The Spaceship Company

- Lift kits and aftermarket off road product design for Cognito Motorsports

- Radio controlled scale vehicle design and production for RC4WD

- I have set up 2 machine shops and several process flow control operation configurations

- Within one week, through tool and fixture design, I saved a company $180,000 per year and still going

- As a young machinist, I completed a tool and die/punch press project previously abandoned by the engineering team. The modifications were effective, and the Die was highly productive for the company

- Hole-in-one, on Father's Day, during a golf tournament, with co-workers (Priceless…)